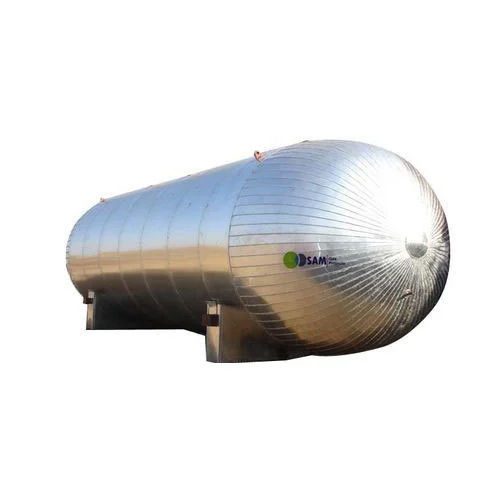

Vessel Puf Insulation Services

Price 80 INR/ Square Foot

MOQ : 100 Square Foots

Vessel Puf Insulation Services Specification

- Service Duration

- Depends on project scope

- Service Type

- Vessel PUF Insulation

- Service Location

- All India

- Application Temperature Range

- -200°C to +110°C

- Coating Finish

- Aluminium/SS cladding available

- Thermal Conductivity

- 0.022 W/mK at 10°C

- Type Of Insulation Service

- Thermal Insulation

- Service Mode

- On-site

- Suitable For

- Storage tanks, vessels, reactors, pipelines

- Adhesion to Surface

- Excellent adhesion to MS/SS surfaces

- Fire Resistance

- Self-extinguishing

- Density of PUF

- 35-40 kg/m³

- Insulation Material

- PUF

- Insulation Thickness

- As per client requirement

About Vessel Puf Insulation Services

Seize this Hot Deal! Our Vessel PUF Insulation Services deliver the ultimate in thermal efficiency, ensuring lavish protection for your storage tanks, vessels, pipelines, and reactors. With a marvelous insulation thickness tailored as per client requirements and a self-extinguishing thermal conductivity of 0.022 W/mK at 10C, it's designed for application temperatures from -200C to +110C. Benefit from excellent adhesion to MS/SS surfaces, aluminum/SS cladding, and dependable fire resistance. Sale now on-Get It Now and elevate your industrial systems with the finest PUF insulation solution, available pan India.

Advanced Application for Marvelous Results

Our Vessel PUF Insulation Services are applied on-site by skilled professionals using modern techniques, ensuring seamless integration and durability. The equipment features double layer insulation, tailored to customer needs, delivering consistent performance. Widely used by leading industries across India, this service enhances energy retention in reactors, pipelines, and storage tanks, providing lavish thermal management. With a PUF density of 35-40 kg/m3 and exceptional adhesion properties, the insulation extends machinery lifespan and boosts operational efficiency.

Transparent Payment Terms & Accredited Delivery

We prioritize fair valuation with transparent payment terms tailored to your project's scope and expenditure. Delivery time is based on project complexity and client requirements; we strive for timely completion to minimize downtime. All services are carried out by certified professionals, adhering to strict industry standards for quality and safety. Trust our solutions to deliver reliability and value without hidden charges. Your investment in PUF insulation is always backed by our commitment to excellent service and recognized certifications across India.

Advanced Application for Marvelous Results

Our Vessel PUF Insulation Services are applied on-site by skilled professionals using modern techniques, ensuring seamless integration and durability. The equipment features double layer insulation, tailored to customer needs, delivering consistent performance. Widely used by leading industries across India, this service enhances energy retention in reactors, pipelines, and storage tanks, providing lavish thermal management. With a PUF density of 35-40 kg/m3 and exceptional adhesion properties, the insulation extends machinery lifespan and boosts operational efficiency.

Transparent Payment Terms & Accredited Delivery

We prioritize fair valuation with transparent payment terms tailored to your project's scope and expenditure. Delivery time is based on project complexity and client requirements; we strive for timely completion to minimize downtime. All services are carried out by certified professionals, adhering to strict industry standards for quality and safety. Trust our solutions to deliver reliability and value without hidden charges. Your investment in PUF insulation is always backed by our commitment to excellent service and recognized certifications across India.

| Insulation Type | Puf Insulation |

| Service Location/City | Pan India |

| Material | PUF |

| Type Of Insulation Material | Polyurethane Foam (PUF) |

| Number Of Insulation Layers | Double Layer Insulation |

| Material Procurement | Customer End |

| Usage/Application | Industrial |

FAQ's of Vessel Puf Insulation Services:

Q: How is the PUF insulation applied to vessels and pipelines?

A: PUF insulation is applied directly on-site by experienced technicians. The process involves surface preparation, layering polyurethane foam (PUF) as per the required thickness, and then finishing with aluminum or stainless-steel cladding for added protection.Q: What are the primary benefits of Vessel PUF Insulation Services?

A: Key benefits include superior thermal insulation with low thermal conductivity (0.022 W/mK at 10C), self-extinguishing fire resistance, broad application temperature range, and extended equipment life due to excellent adhesion and protective cladding.Q: When should I consider using vessel PUF insulation for my facility?

A: Vessel PUF insulation is ideal when you need efficient thermal management, energy savings, or protection for tanks, pipelines, and reactors operating between -200C and +110C, especially in industries with diverse temperature requirements.Q: What is the typical process for ordering and installing the insulation service?

A: The process involves an initial site assessment and consultation, followed by project valuation, material procurement if required, on-site application by experts, and final inspection to ensure quality and compliance.Q: Where can these insulation services be availed in India?

A: Our vessel PUF insulation services are available pan India. We serve a wide range of industries and provide on-site application, no matter the location or project scale.Q: How are payment terms and expenditures determined for this service?

A: Payment terms are set transparently based on the project scope, insulation thickness, and application area. We provide a clear valuation and cost breakdown before commencing work, ensuring there are no hidden charges.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Vessel PUF Insulation Services Category

Vacuum Insulated Storage Tank PUF Service

Price 90 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

PUF Insulated Roof Panel Services

Price 1200 INR / Square Meter

Minimum Order Quantity : 100 Square Foots

Storage Tank PUF Insulation Services

Price 80 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Aluminum Cladding With Puf Insulation Services

Price 80 INR / Square Foot

Minimum Order Quantity : 100 Square Foots

Send Inquiry

Send Inquiry